Hefei Hongye Lithium Energy Science&Technology Co. Ltd.

Contacts:

Lillian

Mobile +wechat+whatsapp:

+86 13570852925

Business phone number:

+86 0551 66105045

Enterprise address:

No.33 YUZHU Road,High-Tech Zone,Hefei City,Anhui Province. China

Email:

Info@ecolto.com

Shirley.wo@ecolto.com

CTO: Morley.lee@ecolto.com

lifepo4 battery 3.2v 6000mAh Features

lifepo4 battery 3.2v 6000mAh Features

(1),fast charging

(2)Safety performance

(3)Long cycle time

(4)Green power

(5)Suit for -20 to 55℃ work environment

lifepo4 battery cells 3.2v 6000mAh main specification:

| Items | Specification | Remarks |

| 3.1 Nominal Capacity | 6000mAh | 0.5C Discharge |

| 3.2 Nominal Voltage | 3.2V | |

| 3.3 Discharge Cut-off Voltage | 2.0V | 0.5 C Discharge |

| 3.4 Charge Limited Voltage | 3.65V | 0℃~60℃ |

| 3.5 Standard Charge Current | 0.5 C | 0℃~60℃ |

| 3.6 Standard Discharge Current | 0.5 C | 0℃~ +60℃ |

| 3.7 Rapid Charge Current | 1.0C | 0℃~45℃ |

| 3.8 Rapid Discharge Current | 1.0C | 0℃~ 45℃ |

| 3.9 Max. Discharge Current | 3C | 2.0V Limited Voltage2.0V |

| 3.10 ( ms) (Max. Pulse Discharge Current) | 5C | 10ms |

| 3.11 Internal Impedance | ≤10mΩ | AC resistance |

| 3.12 Weight | About141g | ±2g |

| 3.13 Storage Temperature Range | ≤ one month | 0℃ ~ 35℃ | 2.8V~3.2V |

| ≤ three months | 0℃ ~ 35℃ | 3.0V~3.2V | |

| ≤ a year | 0℃ ~ 35℃ | 3.1V~3.2V |

lfp battery 6000mAh Electrical Characteristics

| Items | Test Conditions | Specification |

| 4.1(Stand & Charge) | (The "Standard Charge" means charging with constant current 0.5C5 to3.65V, then charging with constant voltage 3.65V to 0.01C 5 under 25±2 , ℃ charging time will not more than 3h.) (Use Lithium-ion battery charger, which with an accuracy ±0.05V.) | |

| 4.2Nominal Capacity | (The capacity means the discharge capacity of the cell, which is measured with discharge current 0.5C to cut-off voltage at 2.0V at 25 ± 2℃ rest for 30 minutes after the Standard Charge.) | (Nominal Capacity ≥6000mAh) |

| 4.3 Cycle Life | At 25±2℃, 1C charge to 3.45V and discharge to 2.5V with 1 C discharge current, after 2000 cycles the discharge capacity is measured with 1C discharge current and 2.5V cut-off voltage. | ≥80%Nominal Capacity |

| 4.4(Storage Characteristic) | (Test the cell initial capacity using 0.5C 5 current at 25±2℃ and record,then charg the cells with 45% capacity, then storage for 3, 6, 12 months respectively a 25±2℃and relative humidity of 0%~75%, then the cell is cycled for 5 times with charge with 0.5C and discharge wit 0.5C at 25±2℃, The maximum discharge capacity (longest discharge capacity ) is recorded. | 0.5Cdischarge time: After 3 months storage ≥5.7Ah; After 6 months storage ≥5.46Ah; After 12 months storage ≥5.16Ah) |

| (The cell is charged and discharged using 0.5C at 25±2℃. The discharge capacity is C1. The cell is stored for 28 days in 20 ±5℃ after fully charged and then is discharged using 0.5C at 25±2℃. The capacity is defined as C2.) | (Capacity Retention C2/C1≥85%) | |

| (After the test as C 2 , The cell is charged and dischargedusing 0.5C | (Capacity recoverable ratio C3/C1≥95%) | |

| 4.5(Rate Capacity) | 1. Under the temperature of 25±2℃,the discharge capacity is measured with 0.5 C discharge current and 2.0V cut-off voltage after full charged. | ≥100%Nominal Capacity |

| 2. Under the temperature of 25±2℃,the discharge capacity is measured with 1 C discharge current and 2.0V cut-off voltage after full charged. | ≥98%Nominal Capacity | |

| 3. Under the temperature of 25±2℃,the discharge capacity is measured with 3 C discharge current and 2.0V cut-off voltage after full charged. | ≥96%Nominal Capacity |

lifepo4 solar battery Environment Characteristics

| Items | Test Conditions | Specification |

| 5.1Temperat ure Performance | (Cells shall be charged according to 5.1 and discharged at 0.5C to 2.0 V after full charged. Cells shall be stored for 4 hours at the test temperature prior to discharging and then shall be discharged at the test temperature, The percentage shall be calculated using discharging capacity compared to the minimum capacity. | No leakage, No Appearance defect |

| -10℃/25℃≥50%(to1.8V) | ||

| 0℃/25℃≥75% | ||

| 25℃/25℃≥100% | ||

| 60℃/25℃≥98% | ||

| 5.2Constant Temperature and Humidity | (Under the temperature of 25±2℃, after charging the cell with 0.5C ,then put the cell into the constant temperature and humidity oven with 40±2℃ and 90~95% for 48h,then store the cells at RT for 2hrs, and discharge the cells with 0.5C to 2.0 volts.) | (The cell should be no deformation, no rust, no leakage, no fire, no smoking and no explosion. Discharge ≥98%Nominal Capacity) |

| 5.3 (Free Fall Test) | (The fully charged cell is dropped three times from a height of 1200 mm (the lowest point of the cell) onto a concrete floor. The cells or batteries are dropped so as to obtain impacts in random orientations. After the test, the cell shall be put on rest for a minimum of one hour and then a visual inspection shall be performed.) | (No explosion, No fire, No smoke. The OCV after the test no less than 90% before free-fall test.) |

| 5.4(Vibration Test ) | (A full-charged cell is to be subjected to simple harmonic motion with amplitude of 0.8mm total maximum excursion. The frequency is to be varied at the rate of 1 hertz per minute between 10 and 55 hertz. After the test is completed, And the cell returned to the starting position. The cell shall be vibrated for 90~100 minutes per axis of XYZ axes. The samples should be observed for 6 hours after the test,and also check the weight loss of cells before and after the test.) | (Not explosion, No fire, No leakage, Mass loss ≤ 0.1%) |

| 5.5(Crush Test) | (A full charged cell is to be crushed between two flat surfaces. The force for the crushing is applied by a hydraulic ram exerting a force of 13±1KN. Once the maximum force has been applied, or an abrupt voltage drop of 0 voltage, or 30% of deformation has occurred compared to the initial dimension, the force is released) | (No explosion, No fire) |

| 5.6 (Shock Test) | (The full charged cell has only two axes of symmetry in which case only two directions shall be tested. Each shock is to be applied in a direction normal to the face of the cell. For each shock the cell is to be accelerated in such a manner that during the initial 3 milliseconds the minimum average acceleration is 735m/s². The peak acceleration shall be between 1225m/s² and 1715m/s². The samples should be observed for 6 hours after the test,and also check the weight loss of cells before and after the test. Cells shall be tested at a temperature of25±2℃.) | (No explosion, No fire, No leakage) |

| 5.7 (Altitude Simulation Test) | (The full-charged cells are to be stored for 6 hours at an absolute pressure of 11.6 KPa and a temperature of 20±3 .) | (No explosion, No fire, No leakage.) |

32650 lifepo4 battery Safety Characteristics

| Items | Test Conditions | Specification |

| 6.1 (Short Circuit) | (Each test sample cell is to be short-circuited by connecting the positive and negative terminals of the cell with a Cu wire having a maximum | No fire,Noexplosion;Max.Temp,of battery surface should not exceed 150℃ |

| resistance load of 80± 20m Ω. The sample is to discharge until a fire or exposition is obtained, or until it has reached a completely discharge state of less than 0.2V and the sample case temperature has returned to ±10 of the ambient temperature. Tests are to ℃ be conducted at 25±2℃ and 55±5℃. Cell Condition: Fresh, Fully charged cell.) | ||

| 6.2 (Over-charge Characteristics) | The battery is charged at a 3 C constant current with a voltage limit of 4.8V for 8 hours after fully charged | No fire,No explosion;Max.Temp.of battery surface should not exceed 150℃. |

| 6.3( Over Discharge) | (After standard charge.Cells are discharged at constant Current of 0.2C to 2.0V, and the positive and negative terminal is connected by a 30 Ω wire for 24 hours. Cell Condition: Fresh, Fully charged cell.) | (No explosion, No fire) |

| 6.4 (Hot oven Characteristics) | The fully charged battery is placed the battery in the hot box,then rose to 130℃±2℃in the temperature to 5℃±2℃/min rate , insulation 30min. | No fire,No explosion |

| 6.5(High Temperature Storage Test) | (Put cell into the 80℃ box and keep the cell in the box for 7 hours after it be charged according to 6.1, and then take it out. Cell Condition: Fresh, Fully charged cell.) | (No explosion, No fire) |

| 6.6(Thermal-cold Cycling Performance Test) | (The full-charged cell is placed in 75±2℃ for 6h, and then put the Cell in -40 ℃ for 6h; change temperature time <30min, then repeat it for 10 cycles. Finally the cell is placed in room temperature for 24h. Watch the appearance of cell.) | (No explosion, No fire, No smoke, Open circuit voltage changed not less than 90%, mass loss limit: ≤0.1%) |

| 6.7(Impact Test) | (A test sample cell is to be placed on a flat surface. A 15.8 ± 0.1mm diameter bar is to be placed across the center of the sample. A 9.1Kg± 0.46Kg mass is to be dropped from the height of 610 ± 25mm to the center of the cell vertically. Cell Condition: Fresh, Fully charged cell.) | (No explosion, No fire) |

Q :Do you provide free sample ?

A: Yes, a few pcs free sample can be provided, but freight will be charged

Q: what is the warranty?

A: one year

Q:What is your payment term ?

A: T/T,L/C

Q:do you accepte OEM order ?

A: Yes,you can print yourself logo, also we can provide the design of outlook for your special battery pack

Q :How many cells you can produce per month?

A: 1.8million

Q :What is the mode of transport?

A: usually by sea

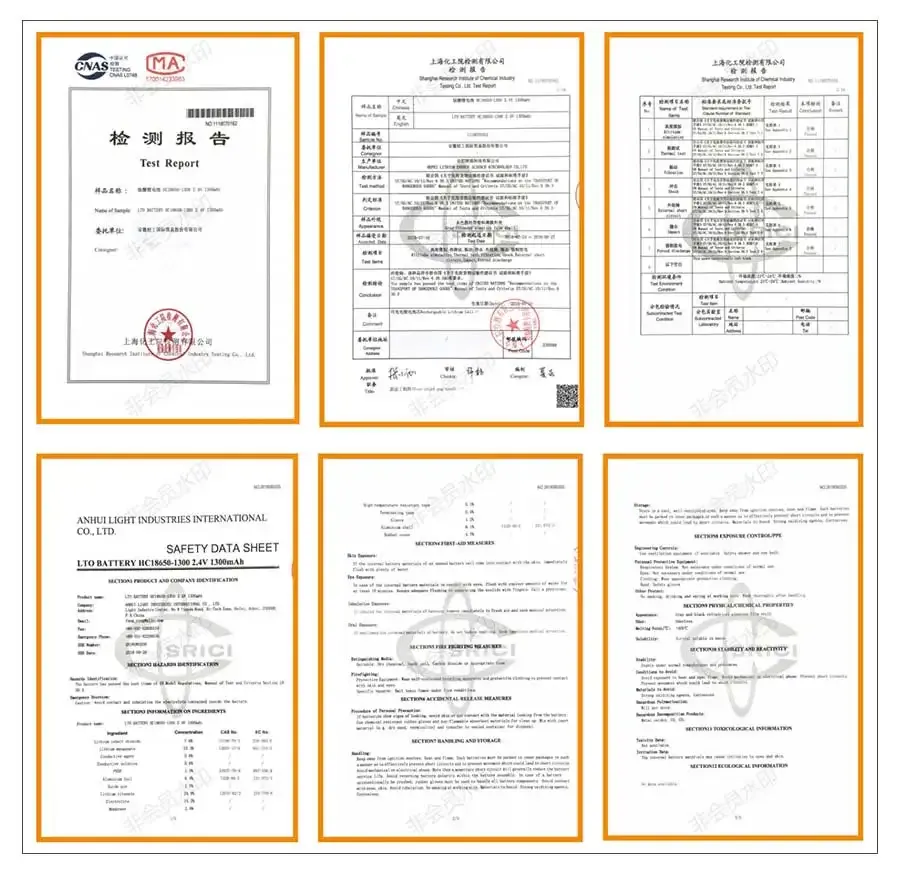

Q:Which certificates do you have

A:We have un38.3,MSDS…etc.

Fill out our short form and we will be contacting you shortly to see we how can provide a solution to your needs!

This site is protected by wp-copyrightpro.com

![]()